Most of the dirt does not come from the exhaust. Up to 70 percent of particulate matter is produced when driving because particles are rubbed off tires, road surfaces - and brakes. This also applies to e-cars. The EU Environment Agency EEA estimates that around 250,000 Europeans die prematurely every year due to excessive particulate matter pollution. So far, the European Union has only regulated the exhaust emissions of gasoline and diesel cars in the so-called Euro standards. With Euro-7, it is now taking on the tires and brakes of all cars. Car manufacturers who still want to sell new cars in the EU after 2026 - i.e. all of them - now need a quick idea of how to reduce wear on their brakes by 80 percent.

Tough nut to crack

A cast-iron car brake disk rotates on the machine's rotary table under laser optics and seven powder feed nozzles. The high-speed laser deposition welding cell, called NaCoat, applies two layers. "In thirty seconds of processing time, the surface layer looks like a chocolate bar with whole nuts under the microscope: The hard particles stick out," explains Lott. "That would not yet reduce particulate matter."

So the brake disk is placed in the NaGrind grinding machine, which grinds the disk smooth with 36 diamond tools. The ultra-hard car brake disc is ready. The wear layer is around ten times harder than standard cast washers and lasts much longer.

On the left, a disk laser feeds two high-speed coating machines. On the right, the panes are given the finishing touches.

The beam does it

Lott: "The idea of hard-coating brake discs is an obvious one. But how?" Three processes were quickly ticked off: electrochemical coating - too dirty. Cold gas spraying - too expensive and not suitable for every windshield.

"But the problems always start when you want to put a good idea into practice," laughs Lott, "cast iron, for example, is a thankless carrier for layers." They simply have difficulty sticking, which is why a lot of powder is needed. Our machine must therefore achieve a high level of powder efficiency, i.e. utilize as much of the supplied powder as possible." How does Nagel now get powder consumption down?

"We have joined forces with TRUMPF in development. And they use a double trick for beam shaping." The BrightLine Weld beam shaping technology divides the laser power into an independently adjustable core and ring zone, a bit like a shower head with a core and ring beam. The second game changer for powder consumption is TRUMPF's bifocal technology: part of the laser beam heats the casting slightly just before the powder shower descends. This means that the powder adheres immediately without any problems instead of bouncing off and turning into expensive waste. Nagel now has an economical production method for Euro 7-compliant, low-abrasion brake discs.

Thanks to the BrightLine Weld solution from TRUMPF, up to 94 percent of the powder adheres to the brake disk during the coating process.

E-car rust problem solved on the side

There's a special treat on top for all e-car drivers: not only can they look forward to whirring through the city with an extra-hard brake disk that is virtually dust-free. The coated windshield also makes the electric car even safer. This is because it is corrosion-resistant and therefore does not rust. And that is particularly good news for e-car drivers. In everyday use, electric cars almost always brake using recuperation, i.e. energy recovery. This creates resistance in the drivetrain, which slows down the vehicle. The mechanical brake disk is rarely used and is starting to rust.

"If you have to make an emergency stop on the highway at high speed, a corroded brake disc is extremely critical to safety: the rust particles that come loose significantly increase the braking distance," explains Lott. With hard-coated brake discs, however, nobody has to worry about this anymore.

Rich and healthy

Car manufacturers and suppliers are preparing for the major Euro 7 changeover. The first car with hard-coated brake discs will probably be on the road by the end of 2025: Extensive tests in test vehicles are already underway. Lott is proud of the business success, but only gushes for a moment before turning serious: "There's something else that's also important: our systems will help people to be exposed to less particulate matter and stay healthy.

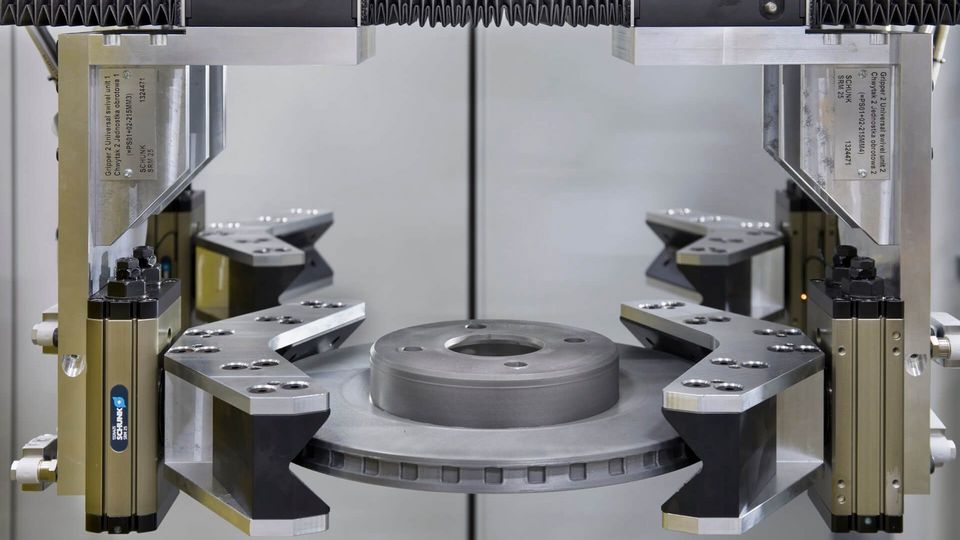

- The grippers grab the brake disk with its raw, untreated cast iron surface and bring it into the coating chamber.

- The high-speed LMD machine applies an ultra-hard carbide layer. Laser heating and beam shaping make maximum use of the powder.

- Cross grinding: The brake disk is given its final surface and geometry in the grinding machine.

Find out more about laser deposition welding of brake discs in accordance with the Euro 7 standard here.